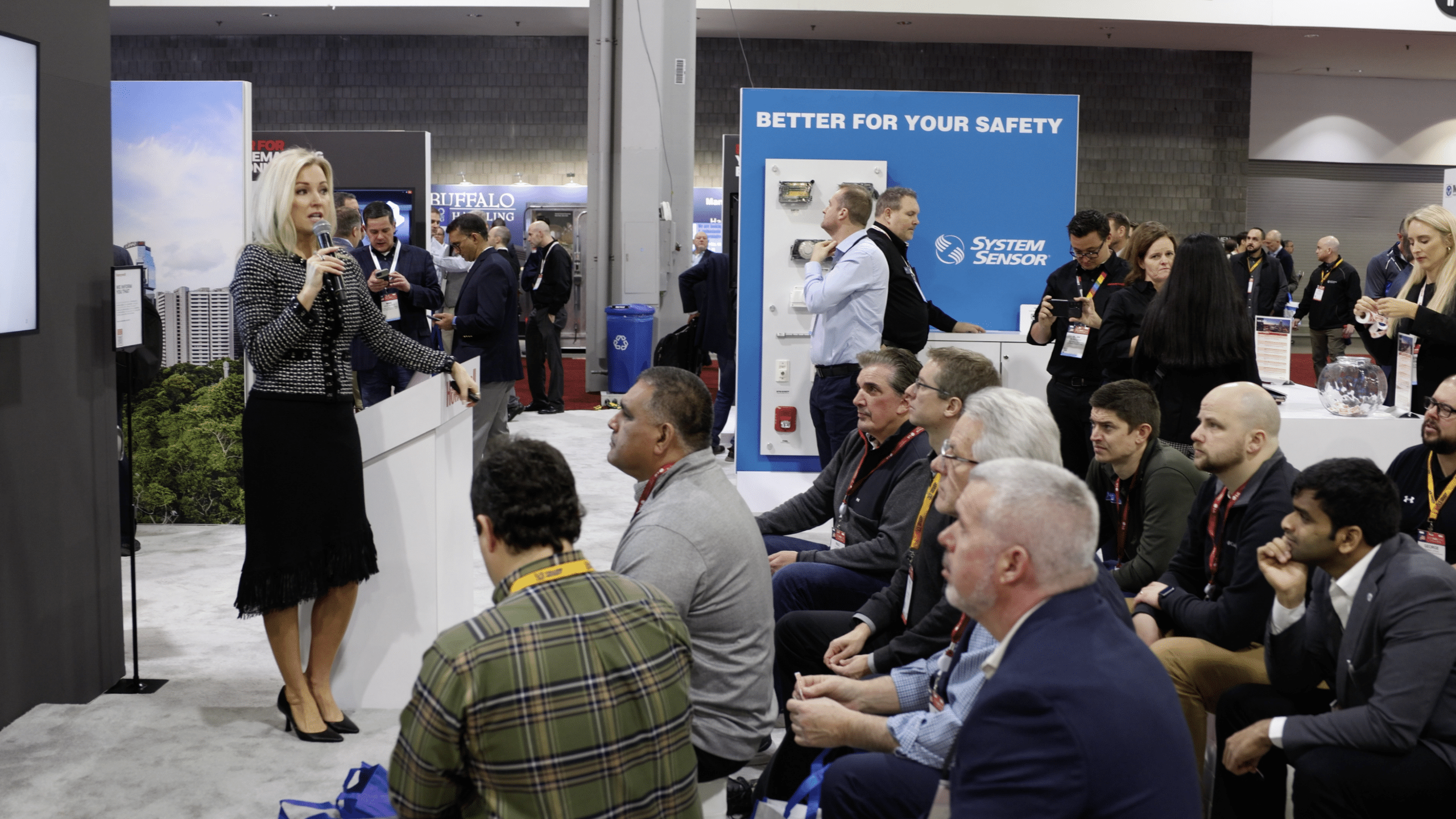

Where Innovation Meets Industry Excellence

Join American Wheatley at the AHR Expo 2024

The HVAC industry constantly evolves, introducing innovative technologies and solutions each year. To stay at the forefront of these advancements, professionals worldwide eagerly await the highly anticipated AHR Expo.

American Wheatley Exhibits at the AHR Expo 2024

As a prominent participant in the AHR Expo 2024, the American Wheatley team is excited to showcase our exceptional HVAC fabrication products and solutions. You can find us at Booth N2714, where our knowledgeable team will be available to answer questions, provide insights, discuss your specific requirements, and explore our extensive product line, including air separators, flex pump connectors, heat exchangers, strainers, tanks, triple-duty valves, assorted valves, and more.

The AHR (Air-Conditioning, Heating, and Refrigeration) Expo is North America’s largest HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) event. It is a global platform that unites industry professionals, manufacturers, suppliers, engineers, and experts from various sectors to showcase the latest technologies, products, and services in the HVAC industry.

Attending the AHR Expo offers many benefits for HVAC professionals and enthusiasts alike. Here are some key reasons why you should attend:

Unparalleled Networking Opportunities:

The AHR Expo is the perfect place to network with industry peers, establish valuable connections, and explore potential collaborations. Conversations with fellow professionals can foster knowledge exchange, facilitate partnerships, and open doors to new opportunities.

Stay Updated on Industry Trends:

As the center of HVACR innovation, the AHR Expo showcases cutting-edge technologies, trends, and solutions. Be the first to experience the latest advancements in energy efficiency, sustainability, smart systems, and more—just by attending the show! This knowledge empowers you to make informed decisions and stay ahead of your competition.

Hands-On Product Experience:

The expo floor is an immersive experience, allowing attendees to interact directly with industry-leading manufacturers and suppliers. You can explore and experience a wide range of HVAC products firsthand, gaining insights into their features, functionality, and applications.

Educational Seminars and Workshops:

The AHR Expo offers a comprehensive lineup of educational sessions, seminars, and workshops conducted by industry experts. These sessions cover diverse topics such as emerging technologies, best practices, regulations, and sustainability. Attending these sessions can enhance your professional skills and expand your knowledge base.

Mark your calendars for January 22-24, 2024, and join us in Chicago, IL, for an unforgettable HVAC experience at the AHR Expo!

Unleash the Pressure of Hydronic HVAC Fabrication Products

Your business is unique, making finding the right products for your specific heating and cooling requirements a challenging task.

At American Wheatley, we designed our business to serve yours. Known for our dedication to quality, integrity, and precision, our state-of-the-art facility houses a dedicated fabrication shop that customizes solutions for your system. In this facility, we combine skill, experience, and automation to design and manufacture top-of-the-line products tailored to your precise specifications.

Here are five reasons to work with American Wheatley for your HVAC fabrication needs.

Unparalleled Expertise and Facilities:

American Wheatley has a cutting-edge, 55,000-square-foot manufacturing facility with a dedicated fabrication shop at your disposal. Within this space, a combination of skilled artisans and advanced automation techniques work perfectly to produce solutions that fuel your day-to-day operations. Our engineers can design a tank that meets your system volume needs while ensuring it fits into the available space footprint.

Whatever custom components you may need, American Wheatley’s team ensures that every step of the fabrication process is meticulously executed—from conceptualization to completion—resulting in products of unparalleled quality and precision.

Versatile and Durable Fabricated Products:

American Wheatley understands the diverse needs of various industries and offers a wide range of products to cater to all project requirements. Our fabricated products include tanks, air separators, valves, and more, constructed in accordance with ASME Section VIII, Division I, latest edition.

Whether you’re working on a commercial, industrial, or residential project, American Wheatley has the perfect solution to meet your hydronic HVAC needs.

Superior Materials for Superior Performance:

American Wheatley uses only high-quality materials in their fabrication process to guarantee long-lasting performance. Each component, from carbon steel to stainless steel, is carefully selected based on your business’s unique needs. We offer safe products for domestic water applications, including NSF-compliant bladders and 304SS construction.

By incorporating these top-grade materials, American Wheatley’s fabrication products maintain their integrity even in the most demanding environments.

Meeting the Highest Quality Standards:

American Wheatley understands the importance of adhering to industry standards. That’s why many of our fabricated products proudly bear the ASME (American Society of Mechanical Engineers) stamp, a symbol of meeting the highest quality and safety standards. This stamp assures customers that American Wheatley’s products have undergone rigorous testing and inspections to ensure their performance, reliability, and compliance with industry regulations.

Stringent Quality Control Measures:

Quality control is a top priority at American Wheatley. Every product we create undergoes comprehensive testing to meet and exceed industry standards. Our rigorous quality control measures guarantee the performance and reliability of our fabrication products.

Rest assured that your hydronic HVAC system will operate flawlessly, providing optimal comfort, efficiency, and safety.

American Wheatley ensures its fabricated products exceed expectations by using high-quality materials, adhering to the highest standards, and implementing stringent quality control measures. When you choose American Wheatley for your hydronic HVAC needs, you’re choosing reliability, versatility, and uncompromising quality.

Experience the power of American Wheatley’s hydronic HVAC fabrication products and elevate your projects to new heights. Explore the products we have to offer today!

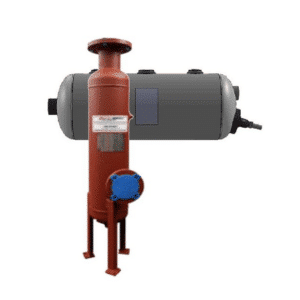

American Wheatley HVAC offers a full range of Shell & Tube and Plate & Frame heat exchangers available in sizes 4″ through 30″, manufactured in accordance with ASME Section VIII. We also offer a complete line of Plate & Frame Heat Exchangers. Whether you’re heating or cooling, these heat exchangers are dependable and powerful with or without fluid separation, American Wheatley HVAC has what you need to complete your projects.

What is a Heat Exchanger?

A heat exchanger is a device that transfers thermal heat from one medium to another. Often this device is manufactured into numerous types of Heat Exchangers such as Shell & Tube and Plate & Frame. All exchangers are an important part of assisting in cooling and heating of homes and business, but also help in machines work more efficiently.

What types of Heat Exchangers are available?

American Wheatley HVAC offers a full range of Shell & Tube and Plate & Frame heat exchangers which affords higher efficiencies, lower fouling, and modular construction that can easily be field modified. The high turbulence of a plate heat exchanger reduces fouling risks while increasing performance. An optimized PHE will be ½ the size (or less) than an equivalent shell & tube while reaching approach temperatures as low as 2°F. American Wheatley’s shell & tube exchangers range from size 4″ through 30″.

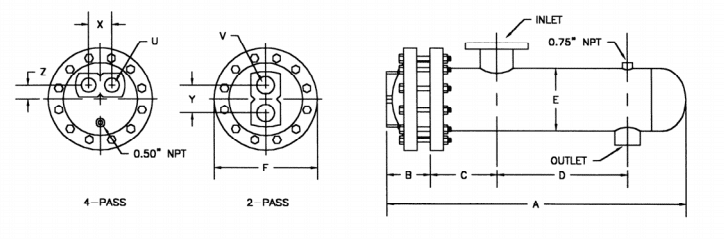

Shell and Tube

Shell &Tube Heat Exchangers consist of a large number of small tubes which are located within a cylindrical shell. These tubes are positioned into cylinders using a tube bundle that is often referred to as “tube sticks” which can either have fixed tube plates or a floating tube stack which allows the tube bundle to expand and contract with varying heat conditions.

Standard Features

- Constructed in accordance with ASME Section VIII

- U-Tube construction

- High degree of flexibility in materials to meet varying conditions

- Available in 2. 4, or 6 pass construction

- All fabrication done in-house

- National board registration

Optional Features

- Additional materials for heads, tubesheets, baffles, and tie rods

- CRN registration

- Optional saddles

- Computerized selections available through authorized HVAC representatives

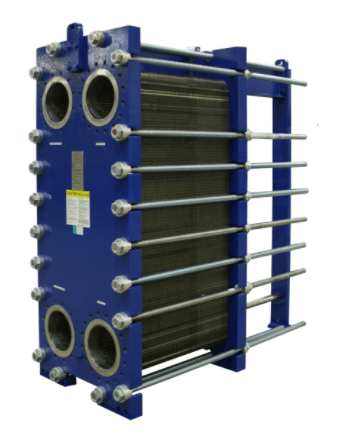

Plate and Frame

Plate Heat Exchangers are operated similarly to Shell & Tube Heat Exchangers, though plates are used instead of tubes. These plates are usually blazed or gasketed depending on the application and fluids being used. This more compact and stainless steel option makes them ideal for use in refrigerants or in food and beverage processing.

Capability

- Port diameter sizes from 1″ to 20″

- Up to 20,000 GPM (4,450 m³/hr)

- Maximum pressure rating of 450 psi

- Maximum temperature rating of 374°F (190°C)

Features

- Modular frame design allows for easy plate pack modification if the working medium or thermal requirements change.

- Optimized plate corrugation ensures even flow distribution across the entire plate surface.

- Tool-less and adhesive-free gaskets for quick maintenance.

- Self-aligning plate pack geometry virtually eliminates plate pack problems even after repeated service.

How Do You Install a Heat Exchanger?

As with any installation, be sure to allow sufficient clearance at the end of the unit for removal or tub bundle. Install the unit so that the pipe connections can be made without forcing them to fit into place. Next, appropriately install the valves and by-passes to permit both the shell & tube bundle to be shut off for inspection, repairs, and cleaning. Finally, the tubing must be full of water before introducing steam or hot water into the shell, otherwise flashing or noise may occur.

Prior to start-up, all nuts should be checked to prevent leaks and blown gaskets. Open the cold side first, then gradually start the hot side, bringing unity to the operating conditions. Always remember to use caution when starting up the heat exchanger and to slowly start up the device to avoid temperature shock to the device.

Need Further Information?

We, at American Wheatley, offer a wide range of options for Heat Exchangers for various usages. Don’t hesitate to contact us for any questions you may have as we are happy to help find the right solution for you!

Contact Us Today!

Due to raw material price increases and ever changing tariffs, we are forced to raise the price of the SGL and DGL glycol pumping systems. The new prices are effective October, 15, 2018.

American Wheatley HVAC Products has entered into a Preferred Master Distributor stocking arrangement with ALLIED TECHNOLOGY & ENGINEERING SERVICES LTD. CO. located in Jeddah, KSA. ATES will stock our WFA and BDT series expansion tanks along with Tangential Style Air Separators with strainers through 16” at their headquarters in Jeddah. Questions and or inquiries should be directed to [email protected]. Allied Technology & Engineering Services is a leader in the HVAC industry in Saudi Arabia and the entire MENA region. American Wheatley HVAC is excited to provide our extensive line of HVAC products and Hydronic accessories throughout the Middle East by engaging this dynamic Preferred Master Distributor.