Our Products

HVAC Tanks

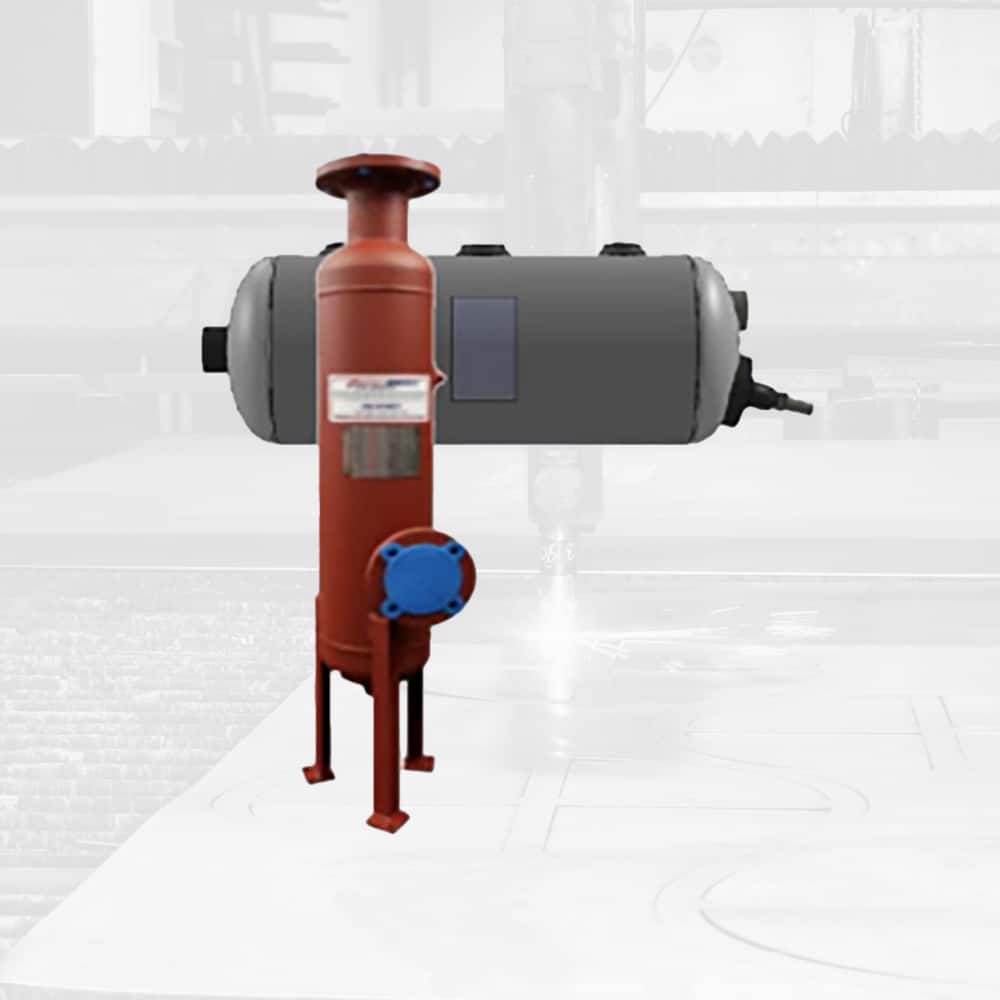

Chilled Water Buffer Tanks

Get Additional Buffer Capacity

Product Details

Chilled water buffer tanks are designed for chilled water systems with insufficient water volume capacity, in relation to the chiller capacity. Relatively low water volume systems require additional “buffer” capacity for the system to eliminate problems such as excessive chiller cycling, poor temperature control, and erratic system operation. The properly sized American Wheatley Chilled Water Buffer tank adds the necessary volume to “buffer” the system. Chilled Water Buffer Tanks are not to be confused with our Hot Water Buffer Tanks. American Wheatley HS Series Hot Water Buffer Tanks are designed to operate with modern high efficient low-mass modular boiler systems. The American Wheatley Hot Water Buffer Tank ensures minimal ΔT and provides the necessary thermal storage to prevent short-cycling that could occur during low load conditions.