Having an air separator in your HVAC system greatly affects the system’s overall performance, especially in a chilled-water system. While air elimination is important in any ventilation setting, it is more important in the chilled-water system than in a hot-water system because the cold-water unit can hold more air inside the tank.

Air separation is a common term when discussing HVAC equipment. There is a wide variety of Air Separators, and there are several uses depending on your needs.

While Dissolved Air Flotation (DAF) is necessary even in a ventilation system with manual vents, it is still very important to consider having an air separator because no hydronic system is airtight. Otherwise, the constant air/water mixture being pumped will dramatically decrease heat transfer efficiencies. A proper air separator also decreases oxygen exposure which is important because oxygen causes a large amount of corrosion that will contaminate the system.

What are the HVAC Air Separator options?

Some options for air separation units are:

- Tangential Air Separators

- In-Line Air Separators

- Sediment-Removal Separators

- Air & Dirt Separators

- Air Purgers or Air Scoops

Along with the outlined air separators, there are also options available for these units such as:

- Strainer

- Less Strainer

- MG – Magnetic Options

If you are interested in a more customized solution, please reach out to us regarding custom fabrication.

How do these Air Separators work?

Each air separator has its own method for air elimination. Below, we describe the outlined options listed above.

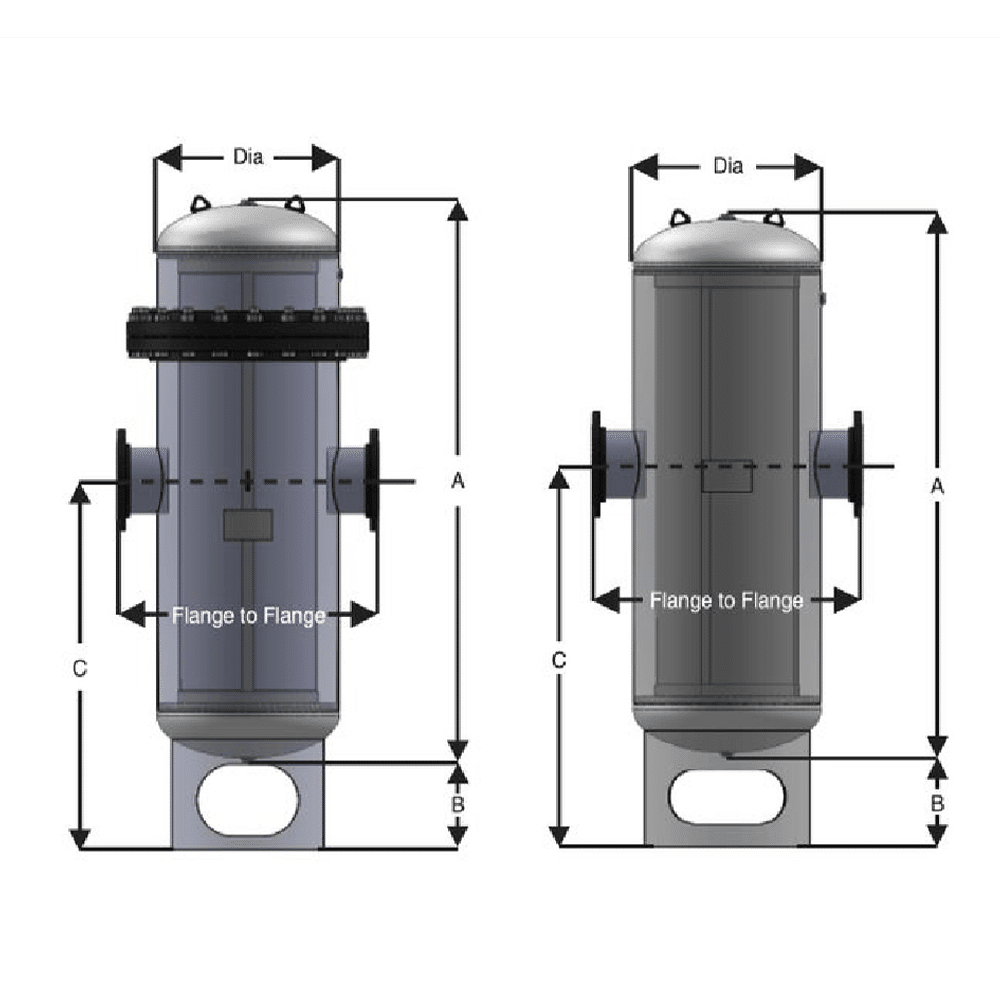

Tangential Air Separators

The Tangential Air Separator design provides air-free fluid flow which protects against damage and system noise. This unit features grooved or flanged inlet and outlet connections. The tangential design results in a smaller unit. There are higher-working pressures available for this air separator.

In-line Air Separators

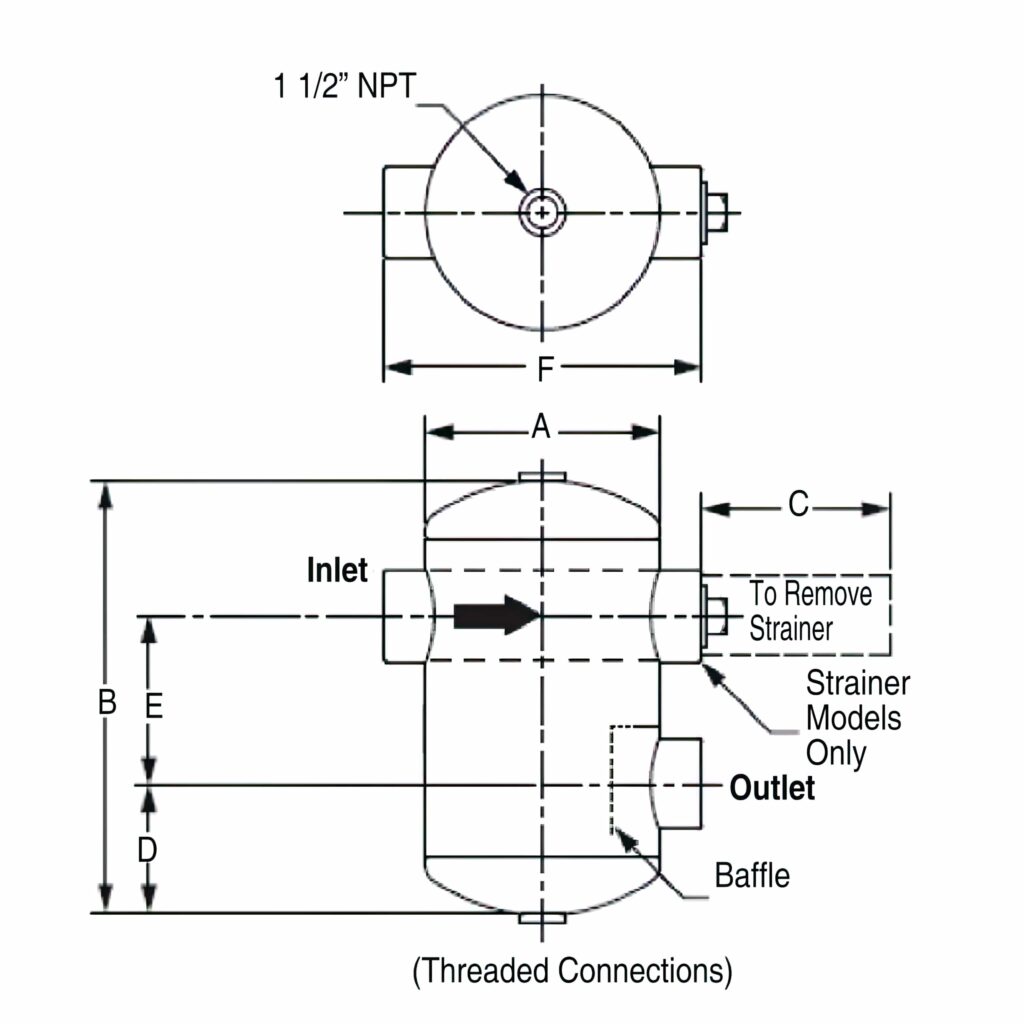

Our In-line Air Separators series offers a lower-cost alternative for air separation in hydronic heating and cooling systems. The IAS/IASS series becomes a point of lower system velocity by changing the direction of flow through the device.

This lower velocity along with the change in direction allows air molecules to separate from water. Once the separation occurs, the air rises within the inline air separator. Then, it is discharged through the vent opening at the top of the vessel. This will go to either the atmosphere or an expansion tank.

Sediment Removal Separators

The Sediment Removal Separator (SRS) is a centrifugal-type sediment removal. While the design is similar to the TAS Series Air Separator, the SRS also offers the advantage of solids removal.

The tangential design allows for sediment removal through the vortex action, which forces suspended sediment to the outside of the vessel and into the bottom sump. You can then easily remove the sediment. The tangential action also creates a vortex that forces entrained air into the center and removes it through the top opening. It is then released into the atmosphere or sent to an expansion tank.

Air & Dirt Separators

The High-Velocity and STAD Standard Velocity Coalescing Air & Dirt Separator is intended for use on commercial HVAC, institutional, and industrial applications to remove entrained air and particulate from system water. This is accomplished by the use of a High-Performance saddle ring coalescing assembly internal to the separator.

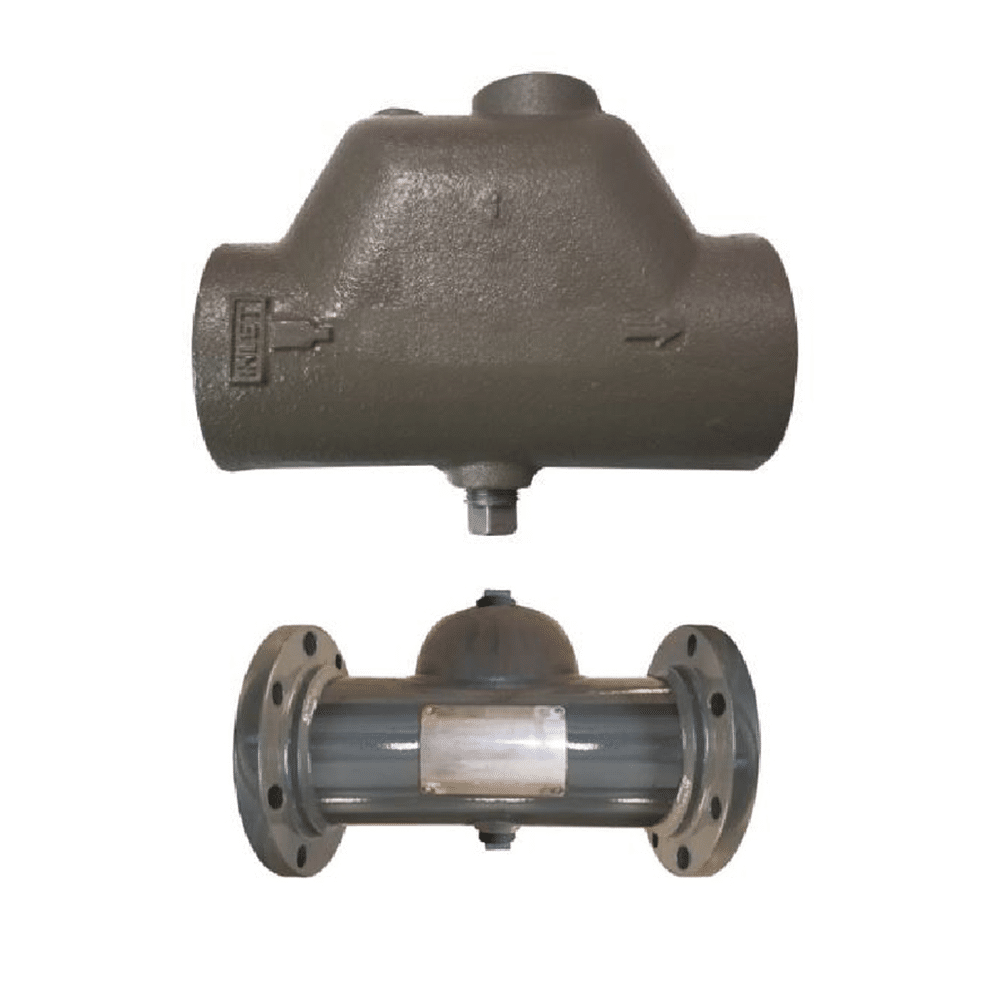

Air Purgers (Air Scoops)

The Air Purger or Air Scoop operates on the premise that air rises in the piping and then into the unit. It is directed to the top opening and out of the system through an air vent or to an expansion tank. Since the proper operation of this type of air separator is also dependent on velocity, sizing this type of air separator is a function of proper flow rate. This type of air separation is best suited for residential and light commercial applications.

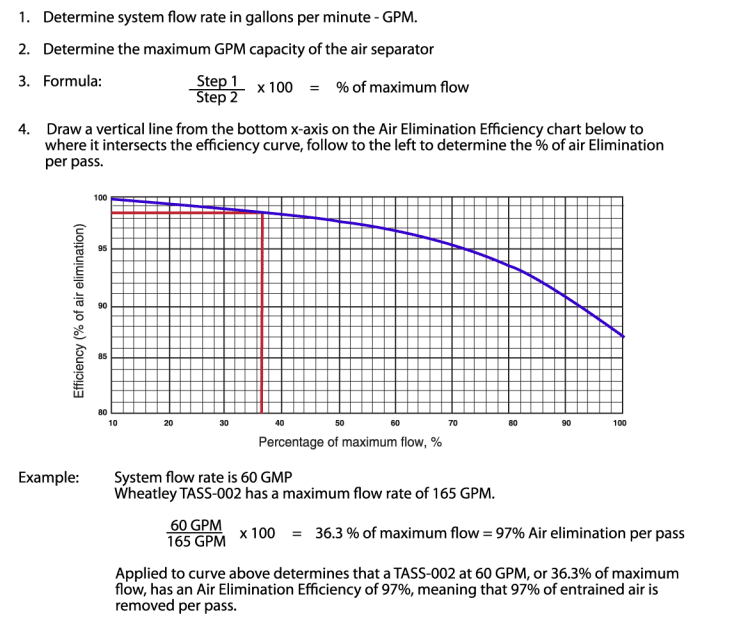

How to determine Air Elimination Efficiency

Need Assistance?

There are plenty of model options available at American Wheatley HVAC. If you are uncertain which of these models will work best for you or need more customization, please reach out to us. We are eager and ready to help you find the right solution for your needs!

* Our American Wheatley HVAC Brand Air Separators are constructed and stamped according to ASME Section VIII Boiler and Pressure Vessel Code requirements and National Board registered.

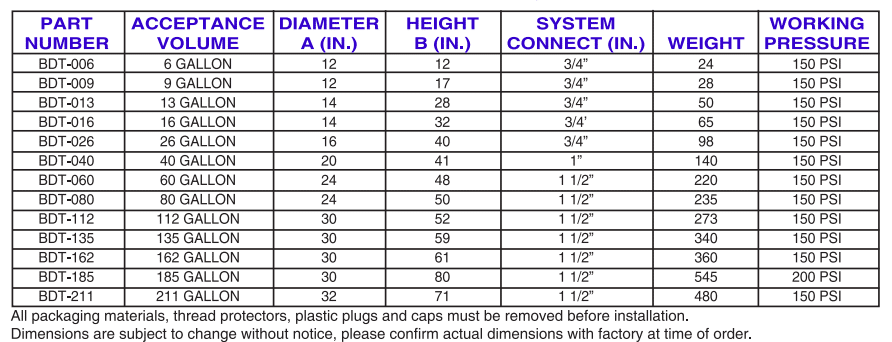

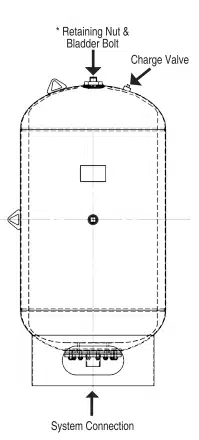

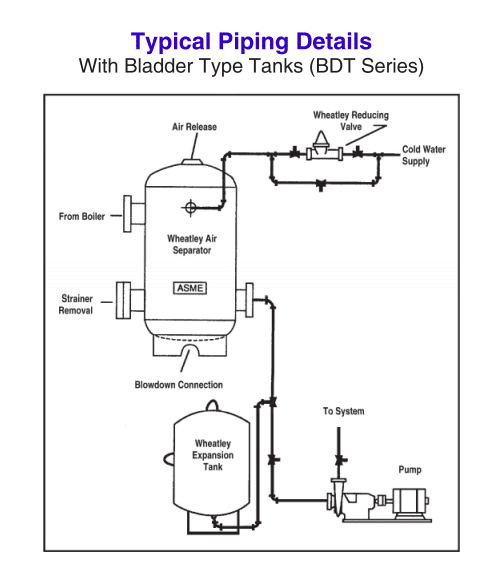

American Wheatley HVAC BDT Multi-Purpose Bladder Expansion tanks are pre-charged bladder expansion tanks constructed to the latest ASME standards.

They are designed for the storage of potable water for pressure boost systems, as well as typical cooling/heating applications. The system’s expanded water is constrained in a heavy-duty bladder preventing tank corrosion and waterlogging problems.

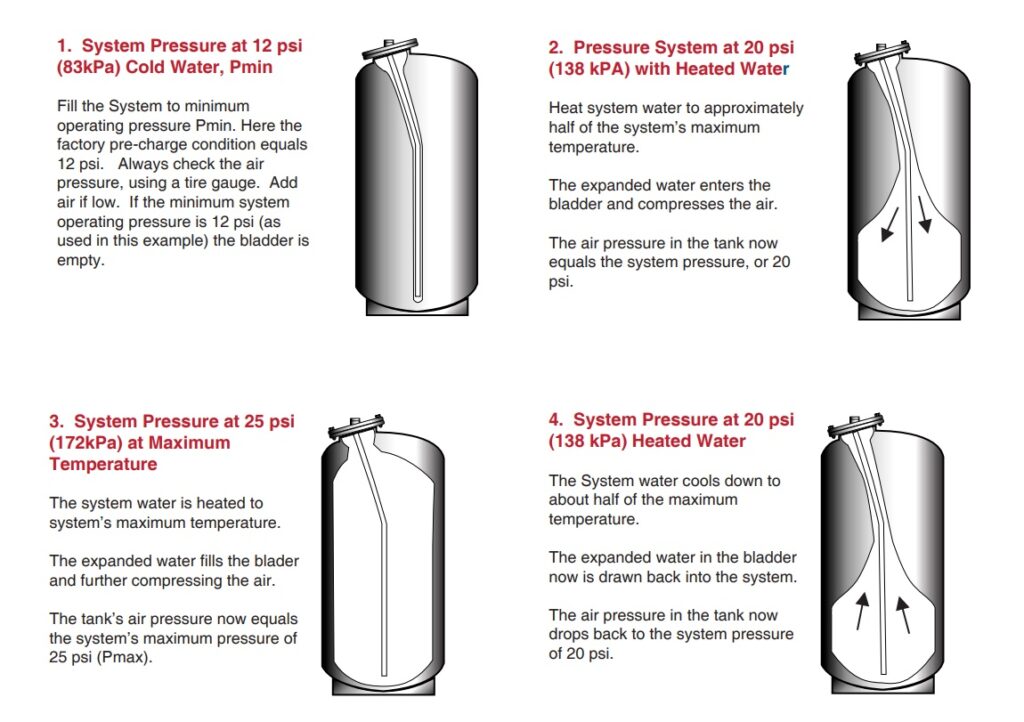

The factory set pre-charge for these tanks is 12 PSIG. The BDT Multi-Purpose Bladder tank is suitable for potable water applications.

What does a Multi-Purpose Bladder Tank do?

Designed to absorb the expansion of fluids in typical hydronic systems, the BDT Multi-Purpose Bladder Expansion Tank is used in pressure-boost systems as well as the typical cooling and heating applications.

Bladder material is suitable for hot water applications. Installation of the tank will help eliminate constant pump use, prolonging pump life and unnecessary blowing of relief valves.

What are the features of a BDT Multi-Purpose Bladder Tank?

Features:

- Constructed in accordance with ASME Section VIII, Division I, Latest Edition

- Stainless steel system connection

- EPDM Bladder

- Full Acceptance Bladder Design / Replaceable

- Factory Air Charged to 12 P.S.I

- Maximum temperature 280F Intermittent

- Constructed of NSF 61 Compliant Materials

- Primed Exterior

Optional Features:

- Higher working pressure available

- Top entry

- “Bulls Eye” sight glass

- Seismic mounting (clips or legs)

- Painted Exterior, Epoxy Coatings

Is a Bladder Expansion Tank necessary?

An expansion tank is always highly recommended if you have a ‘closed-loop system’ caused by any kind of check valve or pressure regulating valve installed on your house’s water supply line.

How do Multi-Purpose Bladder Expansion Tanks work?

How do I replace a bladder in a BDT Series Bladder Tank?

1. Isolate multi-purpose bladder type expansion tank from the system. Shut off automatic fill, valve, and drain boiler to release all system pressure.

2. Bleed system air charge through air charging valve. Remove air valve core at top of the tank and discharge remaining air.

3. Disconnect tank from the system.

4. Remove the bolted bottom flange. Prior to removal, mark mating flanges in order to match up properly when reassembling.

5. Loosen and remove the retaining nut on top of the tank. For tanks 26 gallons and smaller, proceed to step 6.

6. Using the chain block and a slight twisting motion, slide the bladder out of the tank. Remove the bladder retaining bolt from the inside of the bladder.

7. Clean up any remaining water, dry out the inside of the tank and clean out any remaining dirt or foreign particles. Check the inside of the tank for any sharp edges that may cut the bladder.

8. Place bladder bot inside new bladder secured with 1/4″ All Thread Rod threaded into the top of bladder bolt. Roll up the bladder as necessary and pull through the tank with a threaded rod.

9. Secure bladder bolt to the top of the tank with retaining nut. Hand tightens at this point. For tanks 26 gallons and smaller, proceed to step 10.

10. Position the bottom neck of the bladder in the bottom of the tank opening to act as gasket sealing surface for system connection.

11. Replace the bottom flange, align the marks and tighten the bolts evenly, using a star pattern.

12. Tighten all threaded and bolt connections.

13. Using compressed air source and pressure gauge, apply 10 psi air pressure to the flange connection then relieve pressure. These actions should ensure proper positioning of the replacement bladder within the tank.

14. Reassemble the air valve at the top and seal the hanger opening.

15. Pre-charge tank to fill pressure or minimum operating pressure.

16. Using soapy water, check the air valve, retaining bolt, and nut, and bottom flange joint for leakage.

17. Reconnect the system, open the fill-valve and check the operation of the tank. Always pre-charge the tank before completing this step.

Furnished and installed and shown on planes, American Wheatley BDT series, full acceptance expansion tank. The tank shall be constructed of carbon steel in accordance with ASME Section VIII, Division 1, latest edition. The tank shall incorporate a removable and replaceable heavy-duty EODN bladder. The tank shall be supplied with a 12 psi factory air charge. Tanks shall be constructed and ASME stamped for 150 psi working pressure at 240F. Tanks shall be supplied with an exterior high-grade red oxide primer finish. Vertical or horizontal installation is acceptable. Non-replaceable diaphragm-type tanks are not acceptable.

Of course, these are just a few examples of what we have to offer. We will be more than happy to help problem-solve and find you the correct buffer tank that fits your needs. Don’t hesitate to reach out to us today for more information and other buffer tank varieties!