Our Products

HVAC Tanks

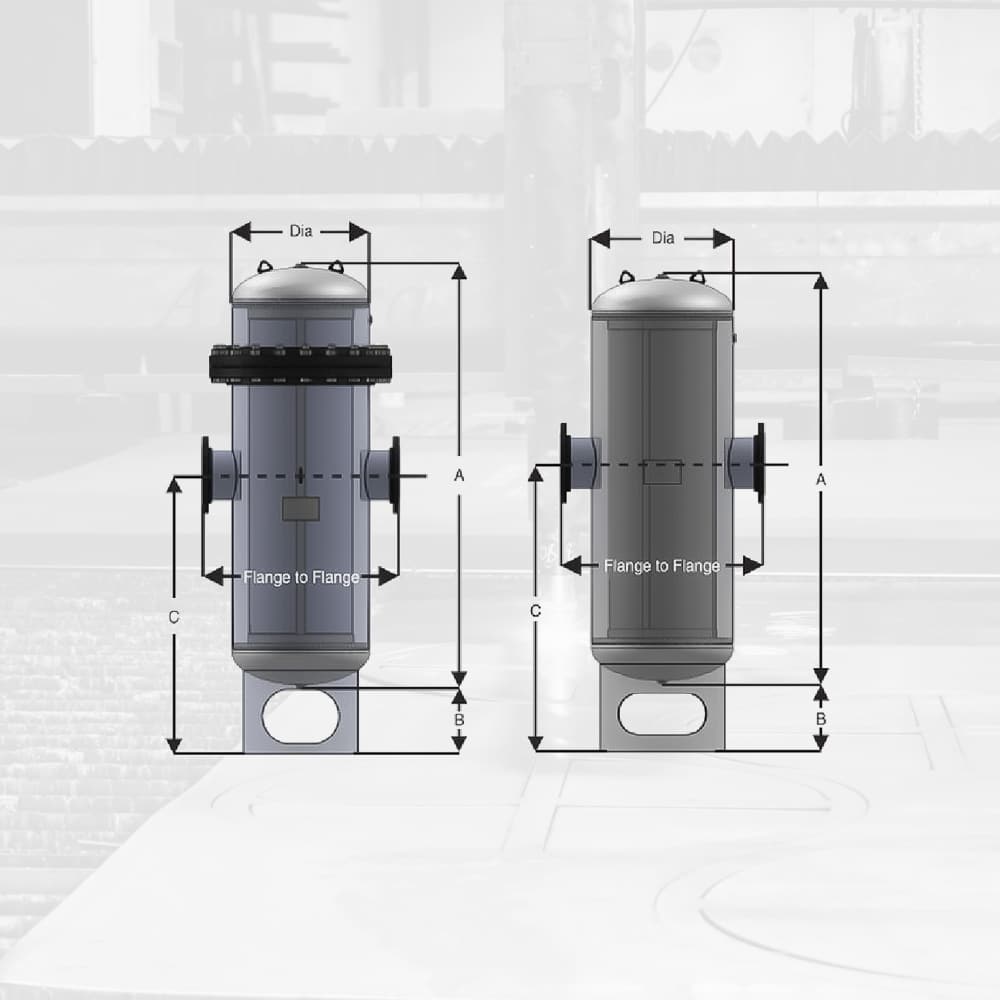

Bladder Expansion Tanks

Hydronic Heating and Cooling

Product Details

Bladder expansion tanks are needed in hydronic heating and cooling systems to absorb the expansion force that results from temperature changes of the heating and cooling fluid. This prevents water logging and air absorption as well as prevents excessive corrosion.

Our bladder expansion tanks are constructed in accordance with the latest ASME Section VIII, Division I standards and ASME stamped. They are National Board Registered and meet the WFA-WBF-WPA standard with a heavy-duty butyl bladder that permanently isolates the fluid from the air cushion within the tank. They also meet the BDT standard with an NSF-listed EPDM bladder and stainless steel cover. All bladders are removable and replaceable.